PUMA-CRETE® Concrete Resurfacer Mortar

Do you have existing brick floor, or a tile floor in your production area, which is showing signs of age? The grout joints are deteriorating? Water leaking through to the floor below? Failing USDA or other inspections? If the deterioration is not too far advanced, our concrete resurfacer mortar EPF flooring may be applied over brick or tile, to provide a seamless, durable and waterproof finish.

PUMA-CRETE® flooring is a unique urethane mortar resurfacing system, which may be bonded to a brick or tile floor. This provides a sealed, waterproof, durable and seamless finish. We also offer an integral cove base at the floor/wall junction, to provide a watertight “bathtub effect” for the entire area.

BRICK FLOOR (BEFORE)

EPF has been serving the food and beverage processing industries for over 30 years. We control all aspects of your flooring project, to ensure a quality, long lasting floor. Services include expert floor consulting, specification assistance, installation with our own crews, and warranty. Options include slope to drain flooring, floor drains, concrete slabs, curbs and more!

EPF provides a single source solution for your food and beverage processing floor needs!

BRICK FLOOR (AFTER)

Alternative to Re-Grouting Brick or Tile

PUMA-CRETE® concrete resurfacer mortar flooring may be applied over brick and tile in many instances. The only requirement is that the majority of the mortar bed under the brick or tile must be structurally sound. The joints and grout between the bricks or tile can even be completely deteriorated. The majority of the bricks or tiles must still be “set” into the base, with no movement.

Repair Brick or Tile?

Grout can be re-grouted, but the drawbacks can be extensive. Proper upkeep is constant, and maintenance costs are high. Repetitive downtime for grouting interrupts production, and is costly. Additionally, re-grouting requires specialty equipment and personnel which may not be readily available. By the time re-grouting is performed, bacteria may have made its way under the brick or tile.

When is Full Replacement of Brick or Tile Required?

In some brick and tile floors, a significant portion of the underlying mortar bed will be deteriorated. This exhibits itself as a large area of loose brick or tiles. In this case, full depth removal is required, of the area in question. If the area is isolated, we may be able to remove and replace the area with a high strength, slope to drain underlayment. Next, we apply our PUMA-CRETE® finish.

If the entire area is structurally compromised, we shall remove the entire brick or tile and mortar bed. In this case, most or all tanks and equipment must be removed to complete the work. We may be able to preserve isolated areas of bricks or tiles (e.g.-under legs and equipment) if requested. This shall require a site inspection to determine.

Clean, Sanitize Brick or Tile?

Clean, Sanitize Brick or Tile?

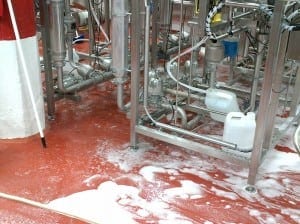

As the tile or brick grout deteriorates, it opens up voids. These gaps allow colonies of E. Coli or Salmonella to enter and grow under the floor. In contrast, PUMA-CRETE® concrete resurfacer mortar sanitary flooring features a seamless non-porous surface. When applied over brick or tile, it serves as a protective seal over the surface. Thus, it prevents infiltration of water, chemicals and microbes. This flooring is easy to clean and sanitize, and resists chemical cleaners.

Apply Epoxy or Urethane Floor over Brick and Tile?

Both seamless epoxy and urethane floors are commonly found in food and beverage processing facilities. Epoxy flooring has many drawbacks in wet processing environments, and has been replaced by seamless urethane flooring over the recent years. Here is a comparison of all the food processing flooring options. PUMA-CRETE® flooring has emerged as the leader, for application over brick and tile floors. The installation may be performed with short down time, while working around tanks and permanent equipment.

We remove any loose and unsound bricks or tiles, refill these areas with fast setting high strength polymer grout. Next, we diamond grind the surface of the bricks or tiles, and overlay brick or tile with PUMA-CRETE® troweled urethane concrete. Our system provides a long lasting, sealed & warrantied waterproof finish!

Fast turnaround installation is guaranteed.

Chemical Resistance of Brick and Tile Floors

Food processing and beverage processing floors are exposed to chemical sanitizers, ingredient spills, hot wash downs and more. Chemical cleaners may include nitric, phosphoric or chlorine based agents. Alkalis such as sodium hydroxide and hydrogen peroxide are often used. These chemicals will deteriorate many grout materials, which can expose the porous tile leveling bed underneath. Our PUMA-CRETE® flooring provides a solution to these tough conditions. It is highly chemical resistant flooring, and designed for high spillage chemical areas typically found on dairy flooring and many other types of specialty food processing plants.

Seamless Concrete Resurfacer Mortar Applied Over Brick or Tiles

Seamless Concrete Resurfacer Mortar Applied Over Brick or Tiles

PUMA-CRETE® flooring is a troweled floor for food processing. It is a seamless and heavy duty urethane flooring. Applied at 1/4 to 3/8 inch thickness, it is durable, easy to clean, slip resistant, and thermal shock resistant. This material holds up to heavy fork truck traffic, impact, abrasion and other conditions typically found in food and beverage plants.

Antimicrobial Finish over Brick or Tile

PUMA-CRETE® flooring can not only be applied over brick or tile, but it also serves as antimicrobial flooring. It contains a special ingredient, which inhibits the growth of dangerous pathogens. It highly cleanable finish can also provide a durable surface for clean room flooring.

Applied Over Brick or Tile for Inspections and Certifications

Many facilities are subject to audits and inspections for compliance programs. Inspectors require a food or beverage processing floor that is smooth, in good repair, dense, non porous and free of gaps and voids. Any deterioration of grout joints in bricks or tiles will likely lead to an inspection failure. Plants often must follow a strict HACCP compliance program. This may also also require inspections and certifications by various agencies. PUMA-CRETE® flooring is USDA approved, SQF approved, IFS, FSSC22000, and BRC compliant.

Thermal Shock and Cycling

Many food and beverage processing facilities install brick or tile floors for thermal shock. However, PUMA-CRETE® flooring handles thermal shock and cycling as well as bricks and tiles. There are several problems with brick and tile. They may be a higher upfront cost, and also require more maintenance. The joints have to be re-grouted (unless they have polymer resin joints, which are much more costly). Additionally, when renovating, all equipment within the area requires removal. The floor must be raised several inches higher, due to thickness of brick or tile plus the mortar bed.

PUMA-CRETE® applied over brick or tile

Since EPF is vertically integrated, we offer a single source turn-key installation of our PUMA-CRETE® applied over brick or tile. This includes expert floor consulting, floor specification assistance, manufacturing and installation. Our systems are installed with our own company crews. Your project shall have a dedicated team including project manager, site manager, team leader, and 6-12 flooring technicians. We provide an exclusive EPF five year warranty at the conclusion of the project. We control and guarantee all the facets of the project, allowing the customer to rest easy, and enjoy the results.

Anti Skid Flooring in Brick and Tile Areas

Brick and tile floor can often be slippery. In wet conditions, they can be especially hazardous with oils or other foodstuffs on the floor. PUMA-CRETE® flooring

Check out advantages over our competition !

Top 10 PUMA-CRETE® Advantages

Food & Beverage Processing Floors – home

Overlay Brick and Tile Options

PUMA-CRETE®

Sloping to Drains

Drain Installation

Sanitary Cove Base

Cleaning Puma-Crete®

More advantages of urethane mortar flooring versus brick and tile

If you would like a quotation or more information on any of our seamless flooring systems, please contact the technical support team at 800-808-7773.

Clean, Sanitize Brick or Tile?

Clean, Sanitize Brick or Tile? Seamless Concrete Resurfacer Mortar Applied Over Brick or Tiles

Seamless Concrete Resurfacer Mortar Applied Over Brick or Tiles