ESD FLOORING

EPF is a leader in ESD flooring solutions for the microelectronics manufacturing and testing markets. We also furnish conductive flooring for specialty manufacturing, warehouse and AGV area flooring. For over 30 years, our vertically integrated company has furnished full service epoxy floor coatings and ESD urethane flooring. We offer turn key responsibility, under one company. No distributors, no sub contractors, just one team working together to provide a cost effective, high quality ESD floor system. Our skilled estimators can help with your ESD epoxy floor specifications, and provide the materials, substrate prep, and installation. Work is guaranteed with a five year warranty. With a nationwide network, we are able to provide localized service throughout the U.S. Our expert installation teams have installed millions of square feet of anti static, polymeric floor systems throughout the United States.

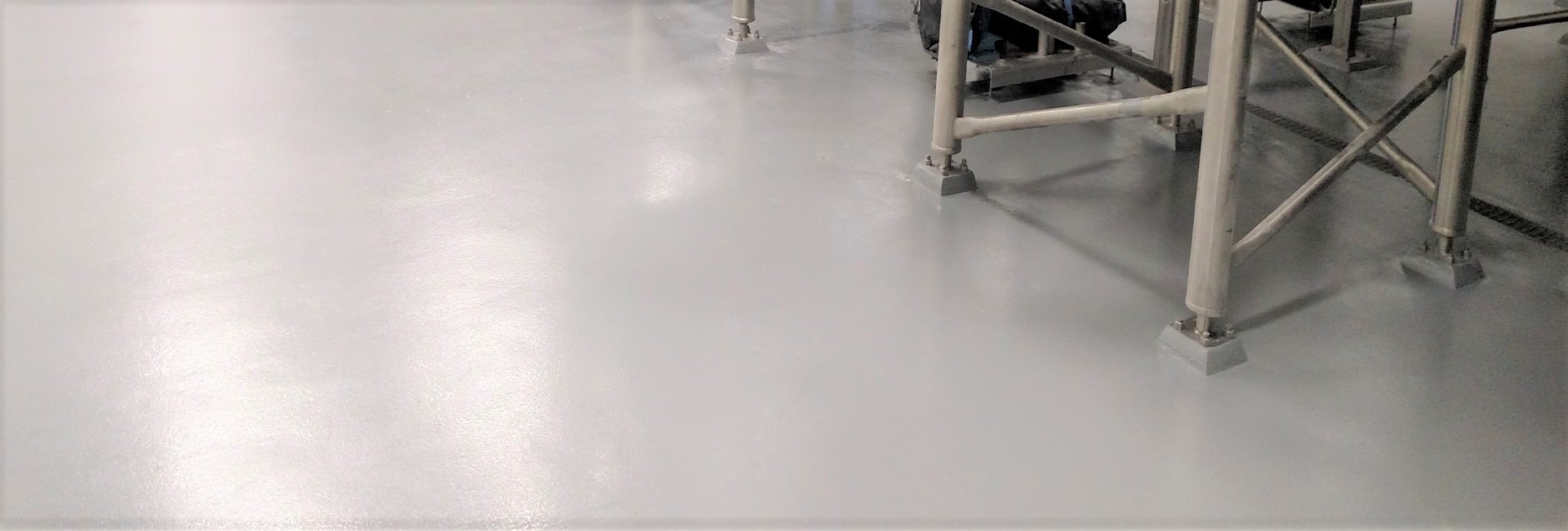

We install PumaCRETE ESD floors, including epoxy floor coatings and high build urethane systems (for heavy traffic areas, or badly damaged concrete). pumaCRETE ESD Our ESD flooring systems are cost effective alternatives to anti static vinyl floor tiles, rubber flooring, and ESD floor paint. Additionally, no waxing is ever required to maintain our conductive properties!

EPF anti static flooring systems provides the lowest long term ESD flooring cost!

Typical Applications for Epoxy ESD Flooring

Typical Applications for Epoxy ESD Flooring

Applications for our epoxy floor coatings include Manufacturing and Testing of Microelectronics, Computer Assembly, PCB Assembly & Configuration, ESDS Device Handling, Automated Assembly, Surface Mount areas, Wave Solder Areas, BGA Re-work, Labs, Repair Areas, AGV flooring (automated guided vehicle), Cable & Harness Interconnect products, PCBA, full box build services and aftermarket repair and fulfillment services.

Project Site ESD Floor Specifications

Customers are provided consultation on ESD epoxy flooring and expert static control needs analysis. For renovation projects, this includes a thorough analysis of existing floor conditions. Our project estimators evaluate removal of existing flooring, concrete cracks, holes, spalls and joint condition. If removal of existing flooring is required, we estimate costs for tile or sheet goods removal, adhesive removal, and any potential concrete moisture issues. For new construction or renovation, our construction experts can also provide detailed ESD flooring specifications.

ESD Floor Renovations

Many of our projects are retrofit of existing facilities, requiring existing floor stripping, prep, patching, and application of new anti static flooring. We typically recommend an epoxy primer and urethane top coat system. EPF can usually salvage the existing concrete slab, using our specialized dust free stripping and grinding equipment. Vinyl tiles and rubber sheet goods can be quickly and efficiently stripped. Glue or adhesive is removed, and the concrete surface is abraded using our special grinders and dust collectors. Joints are cleaned out and filled with a 2- component sealant. For most projects, these would be our typical ESD floor recommendations.

For badly deteriorated concrete, or if heavy traffic conditions are expected, the areas may require our troweled heavy duty PumaCRETE urethane mortar. This would be applied as a base coat, prior to our ESD primer and topcoat. This system costs more upfront, but is can be a wise investment. It will provide decades of long term heavy duty protection for the area.

Turn Key ESD Flooring Systems

EPF provides the pumaCRETE materials, experience, equipment and installation expertise, to get the project completed right. Done once, done right. Our ESD flooring systems are always turnkey….they include flooring which is properly specified, installed, tested and certified to meet electrical specifications and guaranteed.

Our epoxy flooring advantages are numerous. We offer is a very low life cycle cost. Our systems maintain their electrical properties for the life of the system, which can often be 10-20 years of more. Since our floors never require waxing, this can save a typical customer $1 per sq foot or more, each year of operation (10 years = $10/sq ft). The maintenance cost of waxing along, could pay for the cost of the epoxy ESD floor 2 to 3 times over.

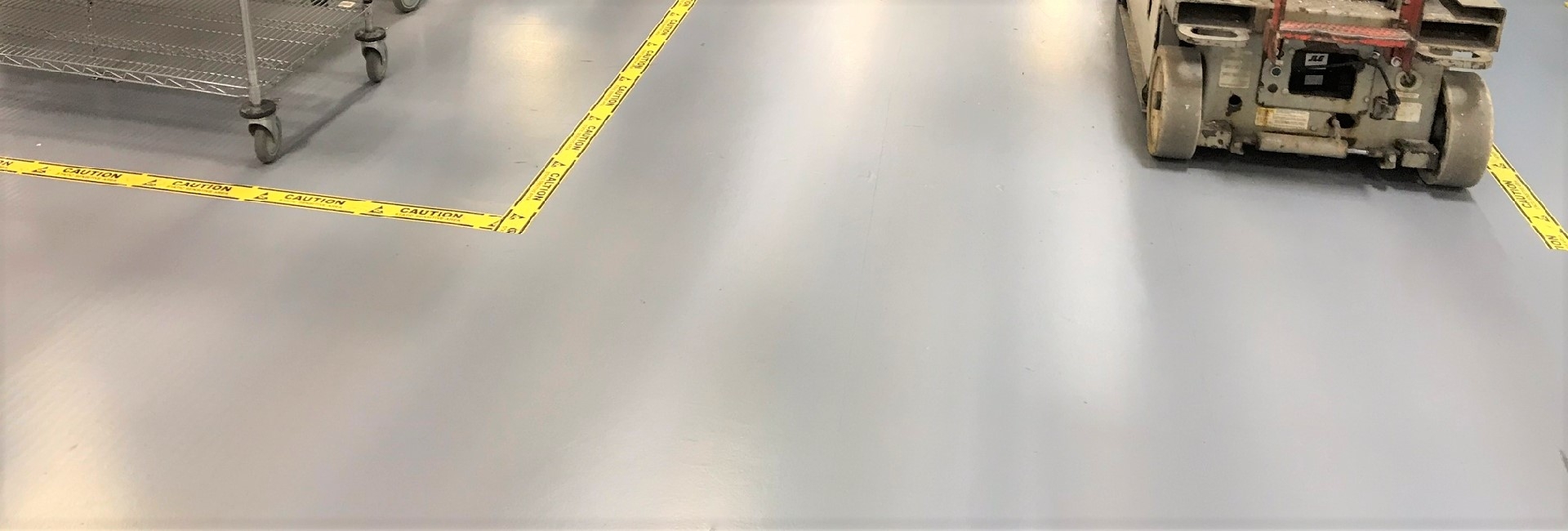

ESD Flooring Installation

EPF trained and certified crews perform an efficient turnaround on projects. Crews are often able to meet very demanding installation schedules. They can complete projects over weekends and brief periods of downtime, with no objectionable odor or dust. We have invested in over a million dollars on specialty surface prep equipment. This helps enable crews to minimize the impact on any production or operations in nearby areas, and perform the installation accurately and efficiently. At the completion of each installation, we test and certify compliance with the required technical standards for the project.

Recent ESD Flooring Installations

Water Vapor Permeable ESD Coating System

Typical seamless flooring and tiles are susceptible to concrete water vapor emission damage. This can cause failure in most seamless and tile systems on the market. Even with extensive evaluation and testing of concrete (and air) relative humidity and temperatures, failures can often do occur. The best protection is to specify a floor system which is vapor permeable. EPF’s epoxy-urethane hybrid system is a breathable ESD floor coating system, which allows water vapor to harmlessly pass through it !

ESD Flooring- ELECTRICAL PROPERTIES- 2 Ranges

Dissipative and Conductive Ranges Available

EPF installs systems compliant with industry standards.

(Electrical properties may also be customized to meet the range needs of our customers)

DISSIPATIVE RANGE 1M-35M ohms

ANSI/ESD 20.20-2014

note: in order to meet ANSI/ESD STM 97.1 and 97.2 requirements, many microelectronics experts have now agreed on a range of 100,000-35 million ohms.

CONDUCTIVE RANGE 25,000-1M ohms

NFPA 99 and DOD 4145.26 Static Conductive 25,000-1M ohms

Walking body voltage generation guarantee <15 volts (using proper footware).

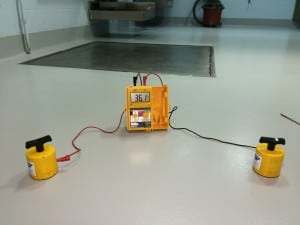

Testing and Certification

Testing and Certification

Immediately after the installation, our floor is compliance tested in accordance with standards in the project specification. ANSI/ESD S20.20 requires that the ESD controls used in a compliant program be verified.

The data is logged, with a minimum of five tests per 5,000 square feet of floor area. A written certification of compliance is issued, after successful completion of the testing procedures.

Grounding for ESD Floor Coatings

The new flooring is electrically grounded, by means metallic tape. EPF installs grounding strips to create a large electrical grid in the flooring, which is properly connected to an earth ground, every “square” or 1500 sq ft.

Clean Room Flooring

For facilities with clean room environments, EPF also specializes in epoxy ESD flooring for clean rooms throughout the medical, military, aerospace, and industrial electronics markets.

Munitions and Flammable Area Flooring

For more information or a quotation on our ESD flooring, please contact a project consultant, for further information at 800-808-7773

CUTTING EDGE, ECO FRIENDLY MATERIAL TECHNOLOGY in the following resin systems:

- POLYURETHANE

- EPOXY

- POLYASPARTIC

- POLYUREA

CUSTOMER FOCUSED

- RELIABLE

- ON TIME

- ON BUDGET

Testing and Certification

Testing and Certification