Slope to Drain Floors for Food & Beverage Processing

EPF can take an existing flat concrete floor, and turn the area into a state of the art processing area, with new drains, floors sloped to the drains, and pumaCRETE urethane finish. Sanitary, durable, functional. One company can handle it A-Z.

Does your processing floor have puddles, low spots, wet concrete, or birdbaths? Are you replacing or moving your floor drains, or re-locating into an existing building with flat floors? In order to provide effective drainage, a floor must be sloped to the drain at a tolerance of 1% to 2% grade. A high strength polymer concrete underlayment can be a cost effective alternative to demolition and removal of the existing concrete slab. For renovation projects, our high strength, slope to drain underlayment system saves time off your schedule, and is cost effective versus full slab removal and replacement.

EPF is a vertically integrally flooring company. We specialize in food processing floors and beverage plant flooring. such as breweries and wineries. EPF developed a cost effective solution for sloping existing concrete floors almost 25 years ago, which provides excellent fluid flow, and eliminates puddles.

EPF is a vertically integrally flooring company. We specialize in food processing floors and beverage plant flooring. such as breweries and wineries. EPF developed a cost effective solution for sloping existing concrete floors almost 25 years ago, which provides excellent fluid flow, and eliminates puddles.

We can manage all aspects of your flooring project, ensuring quality results.

Our services include sloping to drains, stainless steel slot drains, and PumaCRETE finishes. We also provide expert concrete floor consulting, specification assistance, installation of all our products, and exclusive 5 year EPF warranty.

EPF slope to drain pipe flooring helps ensure sanitary conditions and proper drainage for food manufacturing floors. In wash down areas, floors must be sloped properly in order to prevent puddles to comply with food audit inspections and quality control programs.

What Does the Slope to Drains Flooring Process Include?

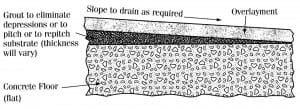

FLOOR SLOPE TO DRAIN DETAIL

Since EPF is vertically integrated, we can manage all aspects of your slope to drain pipe flooring project. This includes expert consulting and specification assistance. If you need a turnkey project, we can also install a stainless steel floor drain system. pumaCRETE materials, and installation with our own crews. We provide slope to drain consulting including assistance with floor drain layout and spacing, floor drainage plan, elevation calculations, and more!

EPF performs the necessary surface prep of the existing floor. Next, our bonded cementitious polymer underlayment is graded at the specified slope. Finally, 1/4 inch thick pumaCRETE® urethane mortar flooring is applied as the final layer. The complete system provides a long lasting floor which drains properly. It is sanitary, chemical and slip resistant.

Options for Enhancing Water Drainage on your Floor

(sorted by lowest to highest cost)

Pre-Fill Depressions and Low Areas Birdbaths can be filled level, using high strength urethane grout. This will raise the low spots, and reduce (but not eliminate) puddling in the overall floor. The depth of the puddles will be reduced, and some puddles may be eliminated. The perimeter edges of the "patched" spots will be visible.

Install Additional Floor Drains Installing more drains decreases the distance that water needs to be moved, to get it to the drains.

Slope/Pitch the Entire Room/Area at 1% to 2% grade This is effective for wide open areas, that can be cleared of equipment. This option can guarantee proper drainage throughout the entire room or areas. The cementitious polymer grout is sloped to the drainage pattern required. Next, a finish (urethane mortar topping) is applied over the slope to drain underlayment, at 1/4 inch thickness, to complete the system. Note that this shall increase the height of your floor, at the perimeter edges of the room/area. For example, at 1/4 inch per foot, this adds 2.5 inch to the perimeter height for every 10 feet from the drain. This means that doorways leading outside the room/area will require ramping down outside the room, due to elevation changes. EPF can help with the design and installation of these transitions, to minimize impact for traffic in/out of the areas. This sloping option typically adds 75-100% to the cost of a PUMA-CRETE® floor project, and a minimum of one day. However, this option is usually more cost effective (and faster) than complete removal and replacement of the entire slab (see option #4). NOTE: sloping must be performed BEFORE the new topping is installed. Once a new finish/topping has been installed, the cost for corrective measures will increase by a factor of 2 to 3 times.

Removal of Entire Slab and Pour New Concrete This option requires extensive noisy heavy demolition, is time consuming, and is usually the most expensive option; for existing production areas, the downtime alone can exceed the cost of the work, when factoring in lost production costs. Excavation and removal operations can open up a "can of worms" underneath, with potential damage to existing sub-slab utility lines and plumbing, soil contamination, etc. This option also requires re-installation of all new drains, adding even more to the total cost.

What if Slope to Drains Flooring is Not Specified for My Project?

Unless a floor section is specified to be sloped to drains, resinous flooring always follow the general contour of the substrate it is applied on.

Chart Describing Drainage for Slope to Drains Flooring Options

| SLOPE % | SLOPE inch/foot | SLOPING EFFECT (for 1/4″ resinous flooring) | |

|---|---|---|---|

| 0 | 0 | No Fluid Flow | |

| 1 | 1/8 inch | Fluid Flows with Assistance for Surface Water | |

| 1.5 | 3/16 inch | Fluid Flows with Some Assistance | |

| 2 | 1/4 inch | Complete Fluid Flow with No Assistance Needed | |

Steps Required for Installation of Slope Flooring

Sloped, bonded, high strength underlayment

- Prep and profile the concrete in all areas less than 2 inches thickness.

- Apply acrylic latex bonding agent.

- Apply 5,000 psi polymer concrete grout, at a slope consistent with the customer’s requirements.

- Saw cut control joints into the slab.

- Apply 401 HFB or HF pumaCRETE® urethane mortar overlayment (typically at 1/4 inch thickness).

- Saw-cut and fill expansion joints in new overlayment with polyurea sealant, to allow movement at building expansion joints.

Turnaround Duration for Slope to Drains Flooring

For up to 2,000 sq ft, a complete turnaround on grading a floor to drains can often be accomplished over a 3 day period. For larger areas, contact one of our flooring consultants, for a project evaluation and estimated timeline.

Slope to Drains Flooring Materials

Various types of industrial flooring and poured flooring are used in manufacturing plants. Epoxy and urethane systems come have been used extensively over the years. Here is a comparison of food processing floor options. Epoxy flooring materials have now mostly been replaced by urethane flooring. Urethane concrete mortar floors have become the “go to” material when companies are looking for seamless flooring. Cementitious polymer floors may also be used as underlayments, for high strength slope to drains flooring.

pumaCRETE® flooring was developed for the food and beverage industries. This food grade flooring is effective when planning to slope an existing concrete floor to drains. pumaCRETE® outlasts other flooring, and is permanent solution. pumaCRETE® typically provides 15-20 years of good service life. It is scrape and gouge resistant, handles thermal shock and cycling, and is anti slip. This is chemical resistant flooring, and may even be applied over brick or tile floors. Flooring may be driven on in as little as 4 hours (with optional polyaspartic top coat), and is perfect for fast turnaround projects,

pumaCRETE® flooring was developed for the food and beverage industries. This food grade flooring is effective when planning to slope an existing concrete floor to drains. pumaCRETE® outlasts other flooring, and is permanent solution. pumaCRETE® typically provides 15-20 years of good service life. It is scrape and gouge resistant, handles thermal shock and cycling, and is anti slip. This is chemical resistant flooring, and may even be applied over brick or tile floors. Flooring may be driven on in as little as 4 hours (with optional polyaspartic top coat), and is perfect for fast turnaround projects,

Check out the advantages we offer, over our competition !

Top 10 pumaCRETE® Advantages

Flooring Inspections and Certifications

pumaCRETE® flooring is well suited for processing areas, warehouses, coolers and any area where food or beverage products are processed or stored. It is USDA approved flooring, meets GFSI guidelines for SQF flooring. pumaCRETE® assists in compliance with FDA and FSMA, as well as HACCP regulations. It also meets IFS, FSSC 22000 and BRC requirements. pumaCRETE® is suitable for use in clean rooms.

Installation of Slope to Drain Flooring

EPF carefully controls all steps of the installation process, for sloping existing concrete floors to drains projects. Each customer is assigned a dedicated project team, which includes a project manager, site manager, team leader and 6-12 flooring technicians. Each step of the installation process is quality controlled, by following time tested checklists for your project. This guarantees a successful project and long lasting floor.

Food & Beverage Processing Floors – home

PUMA-CRETE® SLOPE TO DRAIN FLOOR OPTIONS

Slot Drain Installation

Sanitary Cove Base

Installing over brick or tile

Cleaning pumaCrete processing floors®

For more information, including the color availability, technical properties, or other properties of our slope to drain flooring, please contact the technical support team at our office at 800-808-7773